CO…SP EC Series

Ceramic abrasives break down in a finer manner compared to conventional abrasives, allowing them to maintain their sharpness and sustain their grinding power without losing effectiveness.

Due to their high cutting resistance, the grinding process acts as a cold cutting operation, preventing the workpiece from burning and making it suitable for extended machining tasks.

| Stern | ★★★★☆ |

|---|---|

| Description | Abrasive flap disc, SP – Specialized Applications |

| Applicable Materials | Aluminum alloys, stainless steel, iron, cast iron |

| Applications | Removal of weld beads, rust removal on weld areas, deburring, chamfering |

| Features | Cold grinding, high polishing power, long lifespan, low vibration, and minimal dust generation. When mounted on high-power tools, it maximizes effectiveness. |

| Segments | Suitable for mold repair, automotive parts processing, tank fabrication, steel structures, shipyards, foundries, motorcycle parts processing, etc. |

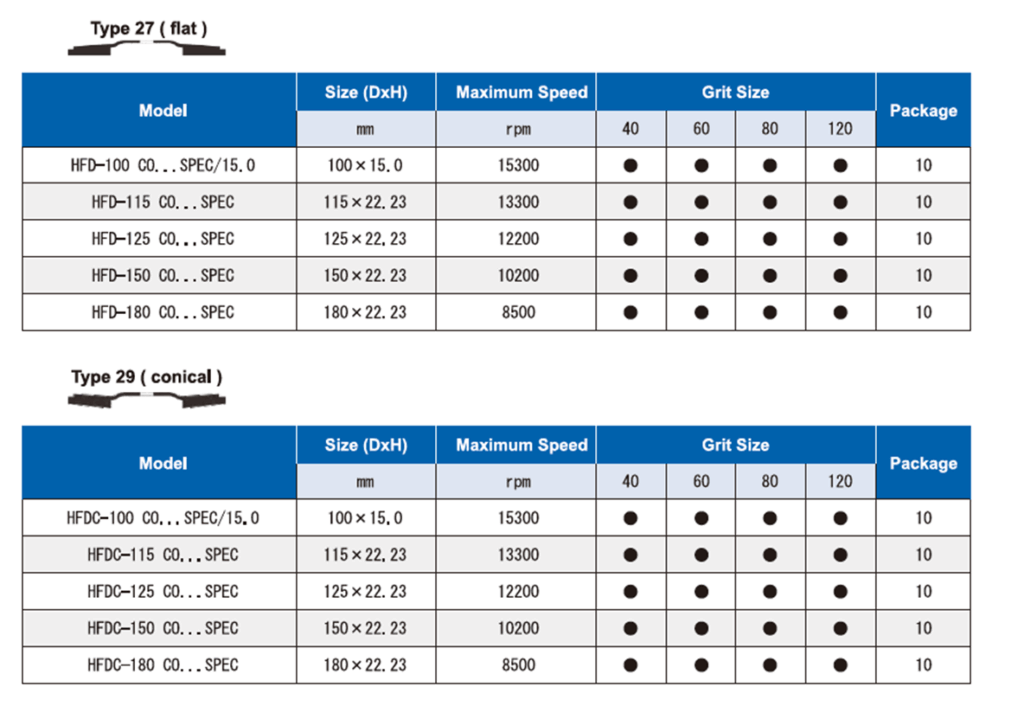

| Order Example | Model number + Grit Size, for e.g. Type 27, dia. 100 mm with grit size #60, the model number will be HFD-100 CO 60 SP-H EC/15.0 |