Applicable Fasteners

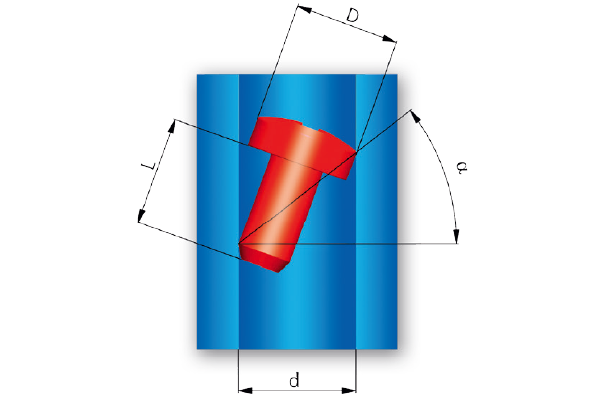

- It can be accommodated as long as the length-to-diameter ratio (L/D) is greater than 1.5.

- For L/D ratios of 1.5 or less, evaluation will be conducted based on actual physical testing.

- Bolts with an L/D ratio small to 1.1 also can be accommodated. Please check with Sun Ken representative in advance.

Driver Bit & Socket

For correct and accurate tightening, it is very important to select right driver bit / socket.

Applicable Sleeve Socket (PAT.)

- Sleeves are manufactured according to bolt specifications and process conditions.

- Hole misalignment tolerance :±3㎜

- Hole angle deviation tolerance:±2.8°

- Long service life

- Allows for quick replacement, reducing downtime and costs.

Applicable Fasteners Variants

Nut

The supply system and tightening drive system can handle the automatic supply and tightening of standard nuts. For special nuts, testing and verification in advance are required.

Bolt & Screw

The supply system and tightening drive system are designed according to the specifications of the bolts/screws. For bolts/screws within the specified size range, automatic supply and tightening are possible.

Blind Rivet, Nut & Stud

Automatic supply of blind rivet, rivet nuts and rivet stud, as well as the joining, can be handled by using the dedicated riveting system.

Stud Bolt

Automatic supply and tightening of double sides studs are possible using the supply system and a specially designed tightening drive system, however, advanced testing and verification are required.

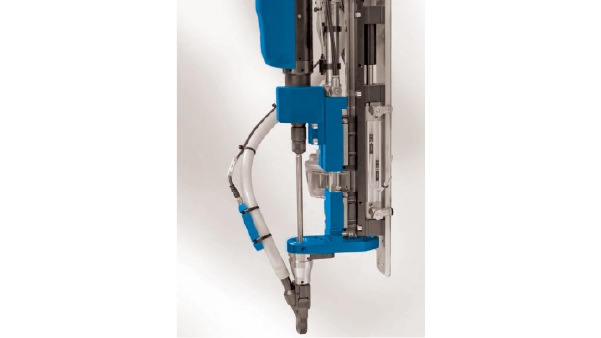

Standard Bolts Drive Units

- Standard Bolts Drive Units

- Customized Bolts Drive Units

- Nuts Drive Units

- Blind Blind Nuts Drive Units

The high-performance HD series Automatic

Fastener Drive Units, when combined with dedicated assembly tools, supports a wide range of torque levels and is compatible with various types of fasteners – covering over 95% of all fastener types. It can be integrated into fastening/riveting systems that handle fasteners of different shapes and sizes, and we also offer customized automatic feeding systems for special specifications.

SPECIFICATIONS

| HD 3100 | HD 3200 | HD 3300 | HDV 3200 | HDV 3300 | |

|---|---|---|---|---|---|

| Max. Dia. of bolt head | 8 | 16 | 25 | 16 | 25 |

| Bolt Size | M2-M4 | M4-M6 | M6-M10 | M4-M6 | M6-M10 |

| Tigtening Products | Electric Assembly Nutrunner/Servo Nutrunner | Electric Assembly Nutrunner/Servo Nutrunner | |||

| Torque Range (Nm) | 0.03 – 5 | 0.5 – 20 | 5 – 60 | 0.5 – 20 | 5 – 60 |

| Speed (rpm) | 10-2500 (according to nutrunner) | 10-2500 (according to nutrunner) | |||

| Vaccum Unit | no | yes | |||

| Vaccum Supply Stroke (mm) | – | 10 – 100 | |||

| Spindle Floating Stroke (mm) | 15/25/50 | 25/50/75/100 | |||

| Min. Dynamic Air Pressure (Mpa) | 0.4 | 0.5 | |||

| Transfer Unit | Servo Moudule, Industrial Cobot & Robot | ||||

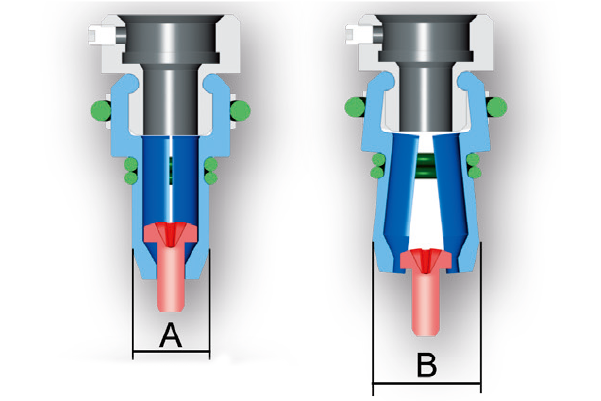

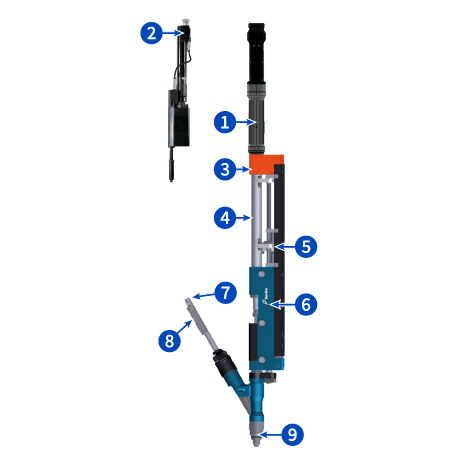

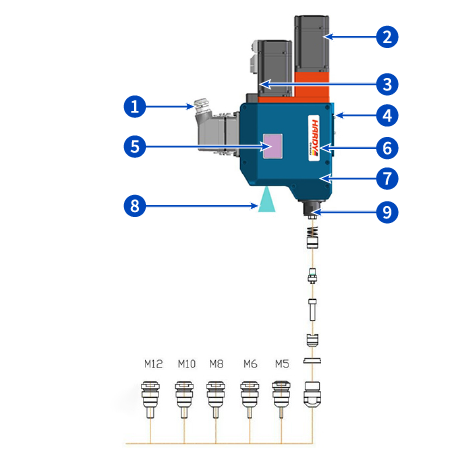

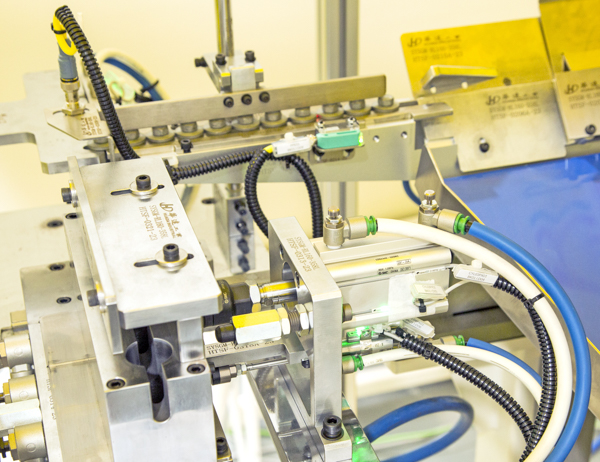

Standard Bolt Driving Unit

- Customizable gun nozzle ideal for assembly in confined spaces

- Modular component structure enables easy maintenance

- Compatible with a wide range of segments (automotive, electronics, offroad machinery, medical equipment, etc.)

- Electric tightening spindle

- Servo tightening spindle

- Adapter

- Feeder cylinder

- Mounting base plate

- Feeding unit

- Supply pipe

- Pipe sensor

- Nozzle

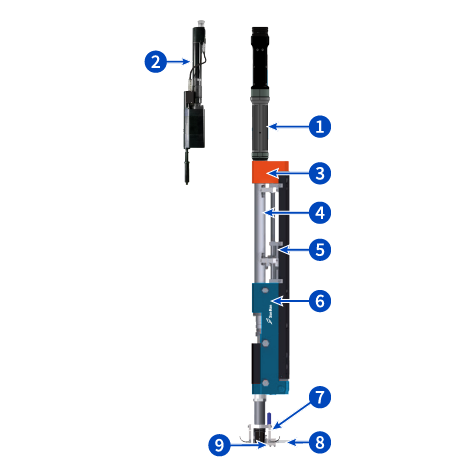

Vacuum-Type Bolt Driving Unit

- Vacuum module design ideal for counterbore and interference fit assemblies

- Vacuum stroke range up to 100 mm

- Suitable for a wide range of segments (automotive, electronics, offroad machinery, medical equipment, etc.)

- Electric tightening spindle

- Servo tightening spindle

- Adapter

- Feeder cylinder

- Mounting base plate

- Feeding unit

- Vacuum components

- Vacuum pipe

- Supply pipe

- Nozzle

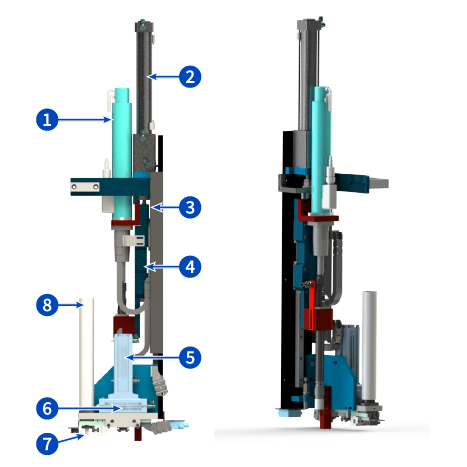

Customized Bolts Drive Units

SPECIFICATIONS

| HDM 4200 | HDV 4300 | |

|---|---|---|

| Bolt Size | M5-M16 | M5-M16 |

| Tigtening Products | Electric Assembly Nutrunner/Servo Nutrunner | |

| Torque Range (Nm) | 3 – 350 | |

| Speed (rpm) | 10 – 2500(according to spindle) | |

| Unit Type | Magnetic Components | Vacuum Components |

| Supply Stroke(mm) | 10 – 100 | |

| Floating Stroke (mm) | 25/50/75/100 | |

| Min. Dynamic Air Pressure (Mpa) | 0.5 | |

| Transfer Unit | Industrial Robot | |

- High-strength design capable of automatic assembly of high-torque bolts

- Special socket supports precise workpiece positioning

- Magnetic and vacuum components adaptable to various tightening conditions

- Applicable across a wide range of segments (automotive body, new energy vehicles, offroad machinery, etc.)

- Servo tightening spindle

- Air supply cylinder

- Mounting base plate

- Slide components

- Extension socket positioning / vacuum components

- Feeding cylinder

- Bolt positioning omponents

- Supply pipe

Nuts Drive Units

SPECIFICATIONS

| HD 5100 | HD 5200 | HD 5300 | HDV 5200 | HDV 5300 | |

|---|---|---|---|---|---|

| Fastener Size | M3-M4 | M5-M8 | M8-M12 | M5-M8 | M8-M12 |

| Tigtening Products | Electric Assembly Nutrunner/Servo Nutrunner | ||||

| Torque Range (Nm) | 0.5 – 20 | 5 – 60 | 20 – 200 | 5 – 60 | 20 – 200 |

| Speed (rpm) | 10-2500 (according to spindle) | 10-2500 (according to spindle) | |||

| Magnetic Unit | no | yes | |||

| Magnetic Supply Stroke (mm) | – | 10 – 100 | |||

| Floating Stroke (mm) | 15/25/50 | 25/50/75/100 | |||

| Min. Dynamic Air Pressure (Mpa) | 0.4 | 0.4 | |||

| Transfer Unit | Servo Moudule, Industrial Cobot & Robot | ||||

Standard Nut Driving Unit

- Custom-designed nozzle enables automatic tightening of nuts

- Modular component structure allows for easy maintenance

- Suitable for a wide range of segments (automotive, electronics, offroad machinery, medical equipment, etc.)

- Electric tightening spindle

- Servo tightening spindle

- Adapter

- Feeder cylinder

- Mounting base plate

- Feeding unit components

- Nut gun nozzle components

- Supply pipe

- Nut positioning components

Magnetic Nut Driving Unit

- Magnetic module design ideal for counterbore and interference fit assemblies

- Special socket allows efficient and stable operations

- Vacuum stroke range: up to 100 mm

- Suitable for a wide range of segments (automotive, electronics, offroad machinery, medical equipment, etc.)

- Electric tightening spindle

- Servo tightening spindle

- Feeder cylinder

- Mounting base plate

- Nut nozzle components

- Supply pipe

- Nut positioning components

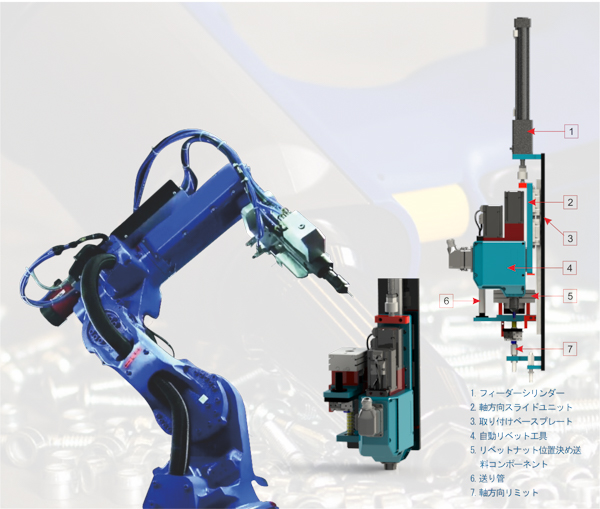

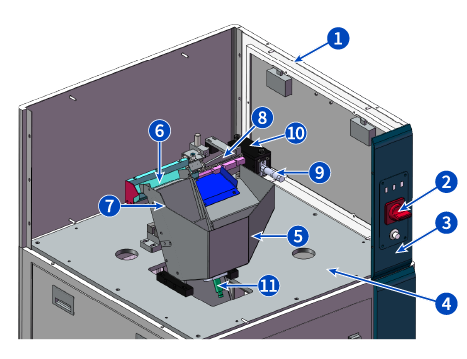

Blind Rivet Nuts Drive Units

SPECIFICATIONS

| HD 9300 | HD 9500 | |

|---|---|---|

| Fastener Size | rivet nut: M3-M12 | Stud bolt: M3-M10 |

| Riveting Type | Servo | Servo |

| Max Setting Force (kN) | 25 | 25 |

| Stroke (mm) | 10 | 10 |

| Max Speed (mm/s) | 23 | 23 |

| Min. Dynamic Air Pressure (Mpa) | 0.4 | 0.4 |

| Transfer Unit | Servo Unit, Industrial Robot | |

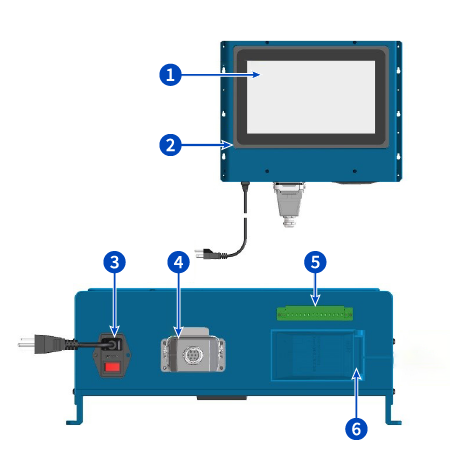

HDAG-8TER Dual-Servo Automatic Rivet Nut System

- Monitors the riveting pressure process

- Monitors the riveting displacement process

- Freely switchable between forward and reverse rotation modes

- Power cable plug

- Rotation servo motor

- Riveting servo motor

- Mounting base plate

- Display

- Stroke sensor

- Pressure sensor

- Camera

- Rivet conversion head

- Management of riveting programs

- Saving of riveting program parameters

- Pressure range setting

- Displacement range setting

- Speed range setting

- Time setting

- Configuration of rivet monitoring points

- Real-time display of pressure curves

- Real-time display of displacement curves

- Stroke vs. setting force relationship curve

- Riveting result information by workpiece number and operation time

- Communication: RS232 , Digital I/O, USB

- Controller

- Positioning alignment

- AC plug

- Control cable

- I/O terminal 3.81mm 15CDGV

- AC200 ~/ USB / RS232

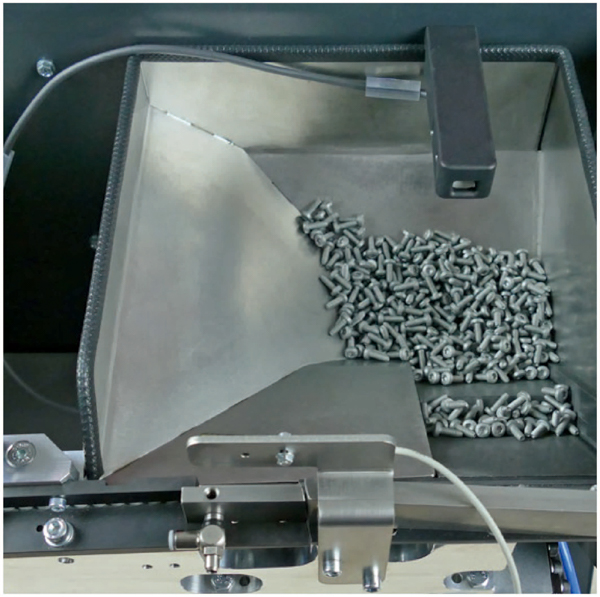

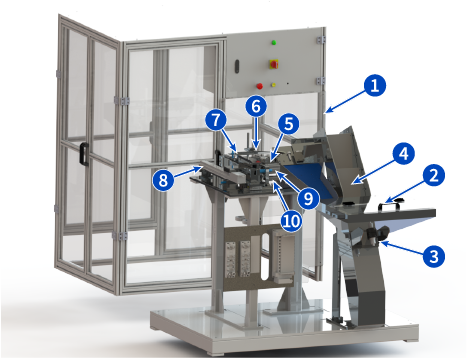

Step Feeder Units

Specifications

| Dimensions (WxDxH) | Step |

|---|---|

| Capacity | 60 pcs / min |

| Channels | 2、3、4 |

| Supply Cycle | 5L |

| Supply Type | 750 x 750 x 950mm |

Applicable Fasteners

| Bolts | M2-M8 length:4-50mm head dia.:3-20mm |

|---|---|

| Nuts | M3-M8 head dia.:3-20mm |

| Stud Bolts | M3-M12 length:4-50mm |

| Rivet Nut | M3-M12 |

| Rivet Stud | M3-M12 |

- Simple design significantly enhances supply stability

- Supply time under 1 second meets the cycle time (CT) requirements of tightening operations

- Modular component design enables easy maintenance

- Compatible with a wide range of fasteners, including bolts, nuts, stud bolts, and rivet nuts

- Box housing

- Power switch

- Ajustmet knob

- Base plate

- Hopper

- Pusher track

- Straight track

- Limit switch

- Distribution cylinder

- Distribution unit

- Fastener level sensor

Step Feeder Units (Large size bolts)

Specifications

| Supply Type | Step |

|---|---|

| Supply Cycle | 30pcs / min |

| Channels | 2 – 10 |

| Capacity | 15L |

| Dimensions (WxDxH) | 1400 x 1000 x 1800mm |

Applicable Fasteners

| Bolts | M6-M16 length:10-80mm Head dia.:8-40mm |

|---|

- Simple design significantly improves supply stability

- Large-capacity hopper reduces the frequency of fastener refills, improving efficiency

- Up to 10 distribution channels supported by servo electric cylinders

- Dustproof design enables use in harsh environments

- Box housing

- Hopper

- Level sensor

- Pusher track

- Straight track

- Limit switch

- Arrival detection sensor

- Distribution servo electric cylinder

- Distribution cylinder

- Sealing cylinder

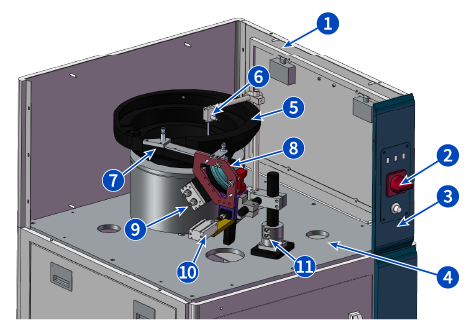

Screw Feeder Units

Specifications

| Supply Type | screw |

|---|---|

| Supply Cycle | 60 pcs / min |

| Channels | 2、3、4 |

| Capacity | 5L |

| Dimensions (WxDxH) | 750 x 750 x 950mm |

Applicable Fasteners

| Bolts | M4-M6 length:6-30mm Head Dia:8-40mm |

|---|---|

| Nuts | M3-M12 Head Dia:3-20mm |

| Stud Bolts | M3-M12 Length:4-50mm |

| Blind Rivet | 2.4 – 6 |

| Rivet Nut | M3-M12 |

| Rivet Stud | M3-M12 |

- The supply channel is customizable, enabling the delivery of various types of fasteners.

- The supply tray is made of specially processed materials, ensuring enhanced supply stability and high durability.

- Supply time is less than 1 second, meeting the cycle time (CT) requirements of tightening processes.

- Compatible with a wide range of fasteners, including bolts, nuts, stud bolts, rivet and rivet nuts.

- Box housing

- Power switch

- Ajustmet knob

- Base plate

- Hopper

- Position sensor

- Straight track

- Distribution unit

- Distribution cylinder

- Stopping unit

- Support frame

Automatic Fastener Supply Control Units

Specifications

| i-HDF 3000 | i-HDF 5000 | i-HDF 8000 | |

|---|---|---|---|

| Supply Type | STEP | STEP | SCREW |

| Supply cycle | 60pcs / min | 30pcs / min | 60pcs / min |

| Channels | 2, 3, 4 | ||

| Capacity | 5L | 15L | 5L |

| Dimensions (WxDxH) | 750 x 750 x 950mm | 1400 x 1000 x 1800mm | 750 x 750 x 950mm |

| Independent Control System | AB exchange, SIMENS, MITSUBISHI, OMRON, SCHNEIDER, BECKHOFF | ||

| Control Panel | 9″ or 12″ | ||

| Communication protocol | Ethernet/IP, EtherCAT, Profinet, DeviceNet, Modbus, IO | ||

- The independent control system enables perfect combination of automatic tightening and feeding processes.

- All tightening drive units are compatible with the above smart control systems.

- An optimized control logic program minimizes on-site adjustment cycles, ensuring smooth equipment installation and operation.

- The target pass rate for automatic tightening and feeding is improved to 99.99%.

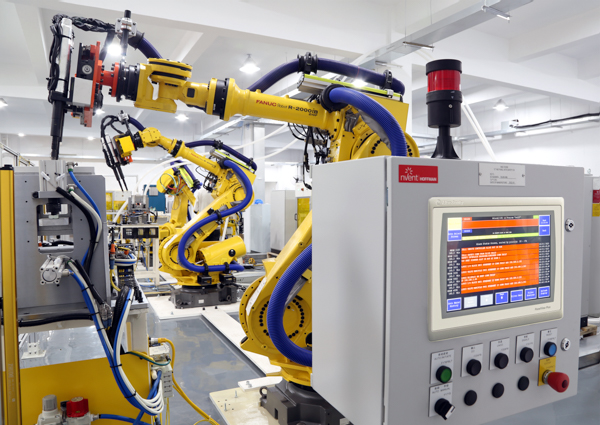

Application references of automatic feeding / assembly solutions

Project Description: Door Hinge Fastening Bolt Automatic Feeding System

- Component: Fastening of door hinges on a four-door vehicle.

- Bolt specifications and quantity: M8 bolt with a 24 mm length and hex washer (8 fasteners per side).

- Pitch requirement: 58 JPH.

- Fixed axle count (one-side): For one set of fastening robots, two sets of actuators are employed with adjustable center-to-center distances.

- Data collection: Tightening torque is recorded and uploaded to the factory server.

- Sleeve: Utilizes a special automatic adaptive magnetic sleeve that accommodates a positional deviation of ±3 mm and an angular deviation of ±2.8°.

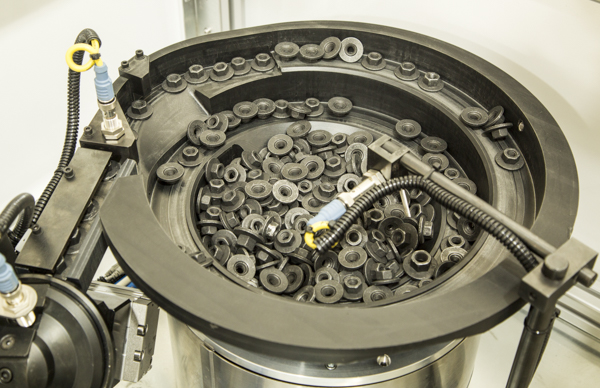

Specific Process

- Two bolts are simultaneously discharged from the vibration feeder.

- The bolts are conveyed through tubes and positioned in the tightening head.

- Two bolts (one upper and one lower) are fastened simultaneously, ensuring secure attachment.

Project Description: A-Pillar Reinforcement Plate Fastening Bolt Automatic Feeding System

- Component: Fastening of A-pillar reinforcement plates.

- Bolt specifications and quantity: M12 bolt with a 35 mm length and hex flange (16 fasteners per side).

- Pitch requirement: 65 JPH.

- Fixed axle count (One Side): Two sets of robots and two sets of actuators with adjustable center-to-center distances.

- Data collection: Tightening torque is recorded and uploaded to the factory server.

- Sleeve: Utilizes a special automatic adaptive magnetic sleeve that accommodates a positional deviation of ±3 mm and an angular deviation of ±2.8°.

Specific Process

- Four bolts are simultaneously discharged from the vibration feeder.

- The bolts are conveyed through tubes and positioned on the bolt installation platform.

- The robot, equipped with a magnetic sleeve, picks up the bolts.

- Fastening

Project Description: Floor Panel Bolt Automatic Feeding System

- Component: Fastening of the floor panel, including the A-pillar reinforcement plate.

- Bolt specifications and quantity: M10 bolt with a 45 mm length and hex washer (7 fasteners per side).

- Pitch requirement: 58 JPH.

- Fixed axle count (one-side): One set of robots and two sets of actuators with adjustable center-to-center distances.

- Data collection: Tightening torque is recorded and uploaded to the factory server.

- Sleeve: Utilizes a special automatic adaptive magnetic sleeve that accommodates a positional deviation of ±3 mm and an angular deviation of ±2.8°.

Specific Process

- Four bolts are simultaneously discharged from the vibration feeder.

- The bolts are conveyed through tubes and positioned in the tightening head.

- Two bolts (one upper and one lower) are fastened simultaneously to ensure secure attachment.

Project Description: Rear Door Hinge Fastening Nut Automatic-Feeding System

- Component: Rear door hinge nuts.

- Bolt specifications and quantity: M8 washer-integrated nuts (4 pcs) and M10 washer-integrated nuts(2 pcs)

- Pitch requirement: 65 JPH.

- Specification: The system automatically transports either M8 or M10 nuts depending on the vehicle model requirements.

- Data collection: Not required (this is a pre-tightening process.)

Specific Process

- The fastening tool automatically switches according to the nut size required for each vehicle model.

- The required number of nuts is conveyed to the platform based on the vehicle model.

- The robot picks up the nuts from the platform.

- Fastening