Product Overview

HAB Series Cordless Shut-off Tool High-Precision Battery Tool

| Recommended Torque Range | 0.8~70Nm |

|---|---|

| Cordless Type | Li-ion Battery-operated 20V,2.5A |

| Torque Accuracy(reference only) | Mechanical Shut-off High Precision (±10% tolerance) |

| Long Service Life | Brushless motor Adoption of contactless switch |

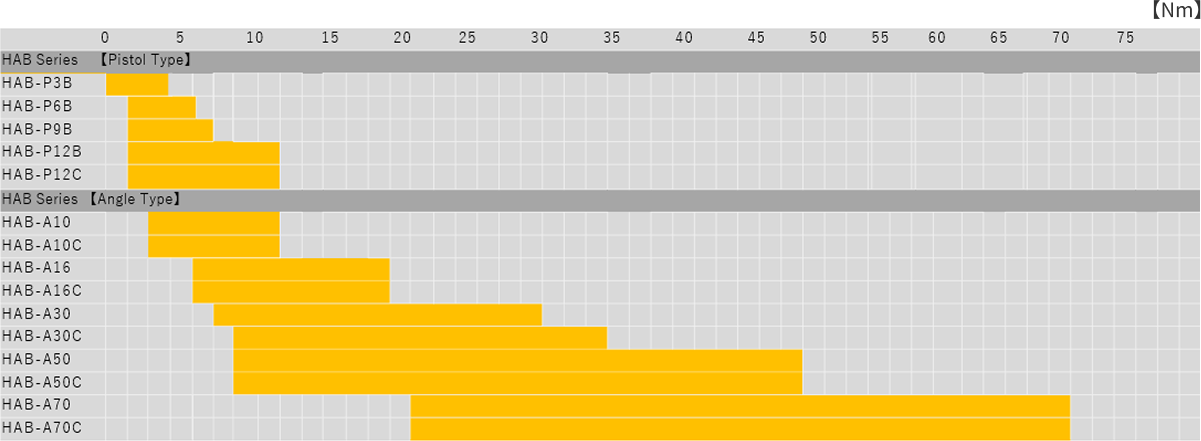

LINEUP

Pistol Type

| Model | Capacity(Nominal Bolt Size) | Drive Size (Sq. or Hex. Size) | Torque Range | Free speed | Weight w/o Battery | ||

|---|---|---|---|---|---|---|---|

| Minimum | Maximum | ||||||

| mm | in | Nm | Nm | min-1 | kg | ||

| HAB-P3B | M3~M4 | 6.35 | 1/4 | 0.8 | 3 | 500-1550 | 1.0 |

| HAB-P6B | M3~M5 | 6.35 | 1/4 | 1.5 | 6 | 300-1000 | 1.0 |

| HAB-P9B | M3~M5 | 6.35 | 1/4 | 1.5 | 9 | 300-800 | 1.0 |

| HAB-P12B | M4~M6 | 6.35 | 1/4 | 2.5 | 12 | 250-800 | 1.0 |

| HAB-P12C | M4~M6 | 9.5 | 3/8 | 2 | 12 | 250-600 | 1.0 |

Angle Type

| Model | Capacity(Nominal Bolt Size) | Drive Size (Sq. or Hex. Size) | Torque Range | Free speed | Weight w/o Battery | ||

|---|---|---|---|---|---|---|---|

| Minimum | Maximum | ||||||

| mm | in | Nm | Nm | min-1 | kg | ||

| HAB-A10 | M4~M5 | 6.35 | 1/4 | 3 | 12 | 400-1000 | 1.6 |

| HAB-A10C | M4~M5 | 9.5 | 3/8 | 3 | 12 | 400-1000 | 1.6 |

| HAB-A16 | M5~M6 | 6.35 | 1/4 | 5 | 18 | 300-600 | 1.6 |

| HAB-A16C | M5~M6 | 9.5 | 3/8 | 5 | 18 | 300-600 | 1.6 |

| HAB-A30 | M6~M8 | 9.5 | 3/8 | 8 | 30 | 250-480 | 1.7 |

| HAB-A30C | M6~M8 | 9.5 | 3/8 | 10 | 35 | 200-330 | 1.7 |

| HAB-A50 | M6~M10 | 9.5 | 3/8 | 10 | 50 | 200 | 2.2 |

| HAB-A50C | M6~M10 | 12.7 | 1/2 | 10 | 50 | 200 | 2.2 |

| HAB-A70 | M8~M12 | 9.5 | 3/8 | 20 | 70 | 170 | 2.5 |

| HAB-A70C | M8~M12 | 12.7 | 1/2 | 20 | 70 | 170 | 2.5 |

- Torque range is a guideline only. Please select tool appropriately according to actual application.

- Model number does not include battery or battery charger. Please order battery and/or battery charger separately

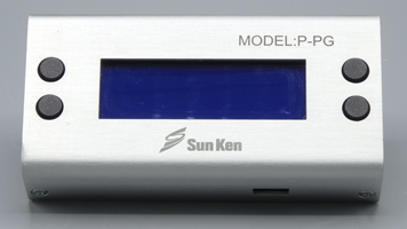

Peripherals for tools

Perform tool settings

Adjust settings such as rotation speed.

The standard battery pack is 2.5Ah (365g).

The 5.0Ah battery pack (630g) is also available.

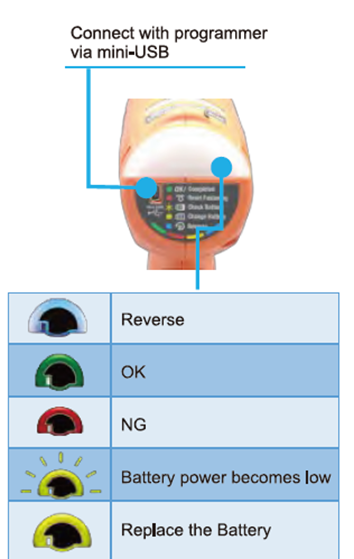

Different Colors for distinguish the torque

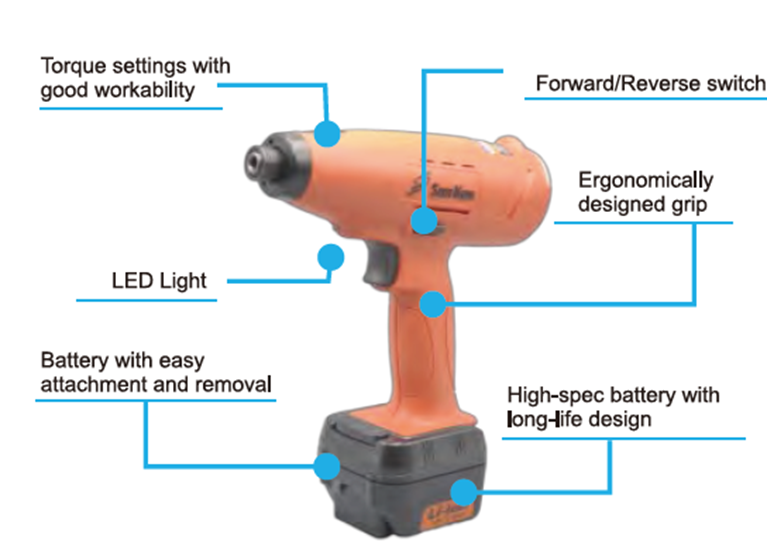

Features

01. LED Display

02. Speed Setting

1.The user can freely set the rotation speed in 50rpm increments within the tool’s speed range.

2.Optimal fastening can be performed according to the characteristics of each fastening point.

03. Slow Start Mode

1.Setting to reduce speed for a certain period during Run Down.

2.Pressing the trigger stats the tool at a slow speed, and after a certain period, it changes to the normal set speed.

3. The duration of the slow rotation can be freely set.

04. Reverse Mode

1.When press the reverse button and push the trigger, the tool starts in reverse operation.

2.Once the trigger is pushed again, the reverse switch turns off, and automatically operates in the forward operation.

Additionally, the reverse switch can be deactivated, allowing for forward rotation only.

05. Double Fastening Detection

If the screw is refastened after fastening, the LED will light up in red for one second with a long beep for one second.

06. Reverse Speed Adjustment

The reverse rotation speed can be set in three stages:

① Same speed as forward rotation.

② Full Speed

③ Approximately 90% of full speed

07. LED Irradiation Time Setting

The LED lighting that illuminates the front workpiece during both forward and reverse rotation can be freely set for a duration of 0 to 60 seconds.

08. Buzzer Volume Adjustment

To warn operator of fastening errors, notifications are provided not only through LEDs but also via a buzzer. The buzzer volume can be set to one to four levels: mute, low, medium, and high.

09.Management Items

The tool’s data includes the total number of fastenings as well as the number of fastenings since the last reset. This information can be used to determine service intervals.

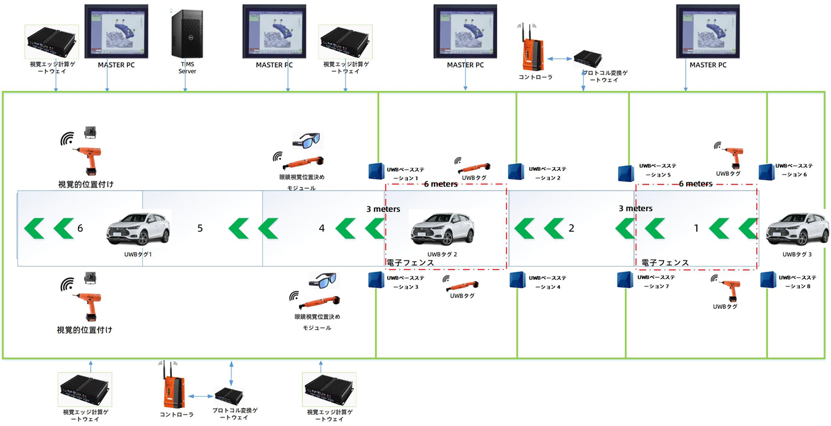

10. Positioning System

11. Recommended Torque